Chopped Fiberglass for Concrete and GFRC - AR Fibers 1/2" - 3/4"

Size:3/4" Fibers - 1 LB

Quantity:

Fast Ship: Usually takes 1-2 business days to ship out.

Ships from Oregon (Click for average Ground delivery map )

)

Ships from Oregon (Click for average Ground delivery map

)

)

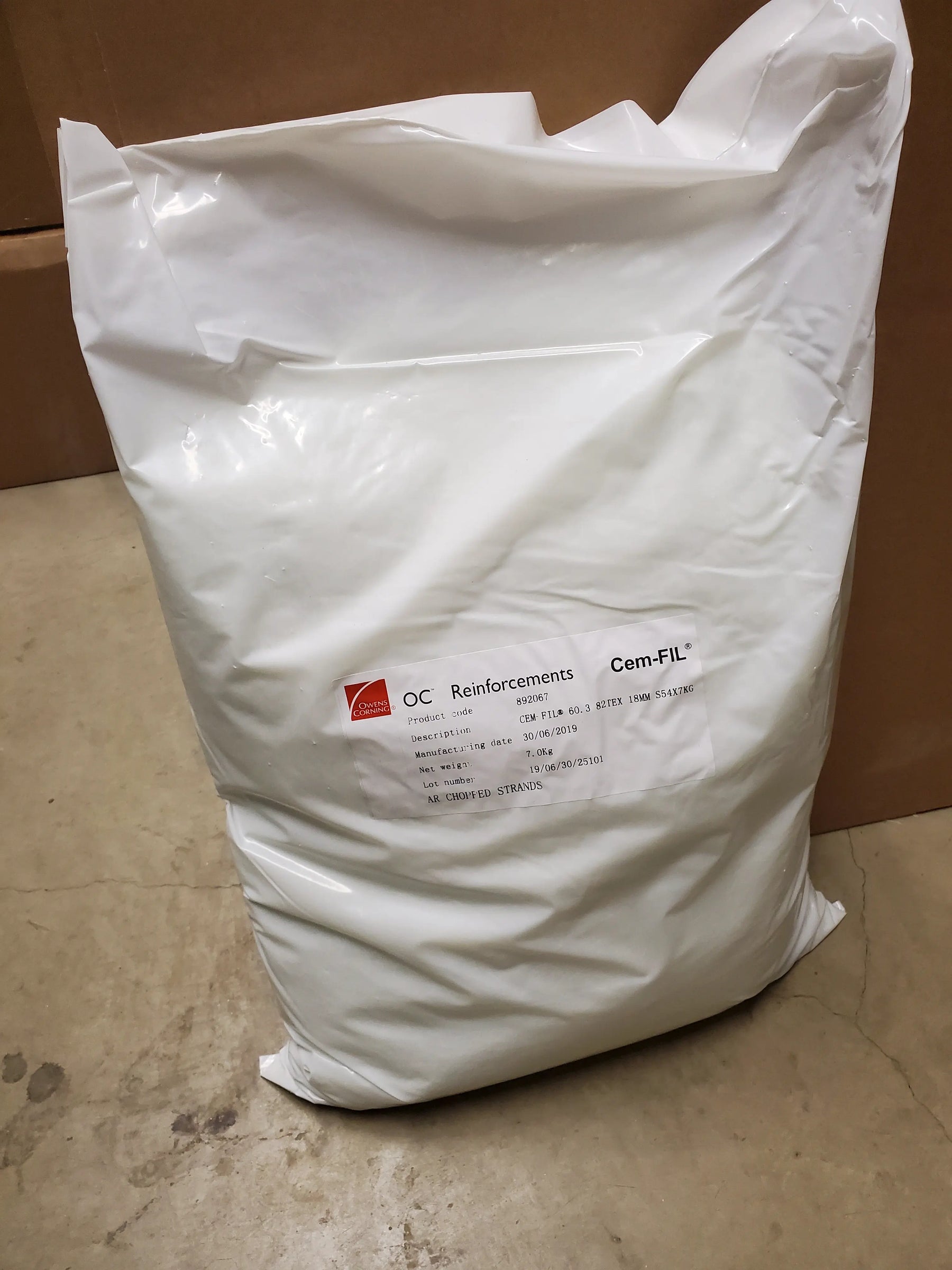

Chopped Fiberglass for Concrete and GFRC - AR Fibers 1/2" - 3/4"

- AR (Alkali Resistant) Glass Fibers, 3/4" length (18mm) and 1/2" length (12mm)

- CemFil 60 fiber is produced by Owens Corning, leading manufacturer of glass fiber containing the highest level of zirconia (to resist alkali attack from the concrete)

- AR Chopped fiber is a must for any GFRC backer coats, but should also be added to any concrete project- every time: From countertops to garages, driveways, patios, etc.

- Cem-Fil 1/2" and 3/4" Fiber is designed to have the same density of the sand in the concrete mix, so with proper finishing techniques the fiber will not be visible on a finished, troweled surface. For Pre-cast concrete, these fibers will also stay away from the surface (sides and bottoms of your forms).

- If you plan to polish the concrete though, you may expose these 1/2" or 3/4" fibers!

- We have a smaller, finer fiber Anti-Crak HD 6mm (sold here) that is suited to mix into concrete that will be sprayed (GFRC Facecoat) as well as other mixes that are on surface to be troweled and you don't want to run the risk of seeing these larger Cem-Fil 1/2"-3/4" fibers)

- Tip: When we at Expressions LTD create concrete countertops that are poured right in place (on the cabinets) we use this larger 1/2"-3/4" fiber in the concrete mix in all but the top 1/2" or so. In the last bit of concrete we place to 'top off' the forms, we use the finer 6mm fiber (sold here) so there is no worry of seeing any of the fiber in the finished project.

Technical Specs Chopped Fiberglass for Concrete and GFRC - AR Fibers 1/2" - 3/4"

- Filament lengths: 3/4" (18mm). 1/2" (12mm)

- 3/4" Size is sold in:

- 1 lb, 2 lbs, 4 lbs, 20 lbs Full Bags, 47 lbs 3-Bag Pack, and Full pallets*

- *Pallets ship freight, which we will ship for free to the US 48!

- 1/2" Size is sold in:

- 28.66 lbs Full Bags, and Full pallets*

- *Pallets ship freight, which we will ship for free to the US 48!

- View CEM-FIL 60 Data Sheet

- Glass Fiber Scrim SDS Sheet (Safety Data Sheet)

Application / Coverage Chopped Fiberglass for Concrete and GFRC - AR Fibers 1/2" - 3/4"

- Typical Dosage (by weight):

- Adding to Countertop Concrete Mixes: 2oz per 80lb concrete mix (1.2oz per 50lb concrete mix)

- Adding to Ready Mix (truck): 1lb to 8lbs, per yard.

- Adding to GFRC Backer Coats: 1.6lbs per 50lbs GFRC mix.

- Maximum Loading/Dosage: 3% of the total concrete mix weight

- Concrete and GFRC mix recipes can be found in our Concrete Recipes section.

- When mixing these fibers into standard Concrete Countertop wet-cast concrete batches, a standard mix ratio is 2 oz. Fibers, by weight, to an 80 lb. bag of concrete. Using this ratio, a 1 lb. bag of Fiber will treat about 8 bags of concrete mix.

- When mixing in Ready Mixed Concrete (trucks), the Fiber can added into the truck on the job site, right before starting the pour).

Even More Technical Stuff about AR Fibers:

- Cem-FIL® alkali resistant (AR) glass fibers have been in use for 40 years in more than 100 countries worldwide to create some of the world's most stunning architecture while offering strong and durable performance in widely varying cement and mortar based applications, including floorings, renders, top screeds, tunnels, utility poles, etc.

- Cem-FIL® AR glass fibers are unique as a concrete reinforcement. Cem-FIL® fibers have the same specific gravity as the aggregates, so assured fiber dispersion is easier to achieve than with other fibers. Cem-FIL® fiber contributes efficiently to the tensile strength before the concrete is able to crack thanks its high Elastic Modulus, its affinity and its efficient bonding with the concrete.

- Cem-FIL® fibers offer superior performance to standard fiber reinforcing with widely varying addition rates designed to meet your specific project specifications.

- Characteristics of Cem-Fil 60

- Appearance: White or off-white

- Physical State: Solid

- Softening Point: 860ºC (1580ºF)

- Melting Point: Non applicable

- Decomposition Temperature: Size and mat binders start to decompose at 200ºC

- Density: 2.6 (water = 1)

- Water Solubility: Insoluble

- Moisture Content: 0.6% (ISO 3344)

- Electrical Conductivity: Very low

- Chemical resistance: Very high

- Modulus of elasticity: 72 GPa - 10 x 106 psi

- Tensile Strength: 1,000 to 1,700 MPa - 150 to 250 x 10³ psi (EN 3361 or EN9163)

- Material: Alkali Resistant Glass (manufactured with high Zirconia content in compliance with ASTM C1666/0 1666/M-07 and EN 15455.)

- Cem-FIL® AR glass fibres are manufactured under a quality management system approved to ISO 9001. Cem-FIL® fibres are not classified as dangerous by the regulation 1272/2008/EC

- Benfits of Cem-Fil 60:

- Excellent compatibility with cement matrix

- Excellent workability even at high dosage

- Increases chemical resistance (e.g. deicing products)

- Improves freeze/thaw resistance

- Extends serviceability of concrete

- Long term durability of concrete

- Does not float or sink in concrete

- Does not entrap air

- Fast and uniform dispersion