Water Based Stain for Concrete - Tru Tint WB

Ships from Illinois (Click for average Ground delivery map

)

)

Shipping: This Product can take 2 to 3 business days to ship out.

Ships via FedEx/UPS only

Ships via FedEx/UPS only

Water Based Stain for Concrete - Tru Tint WB

This is the Quart and Gallon size of our Water-based, penetrating concrete stain. If you want to buy in smaller bottles to try it out: Sample 4oz Size (Sold Here)

- For use on nearly any concrete surface.

- Fast-drying water-based concrete stain

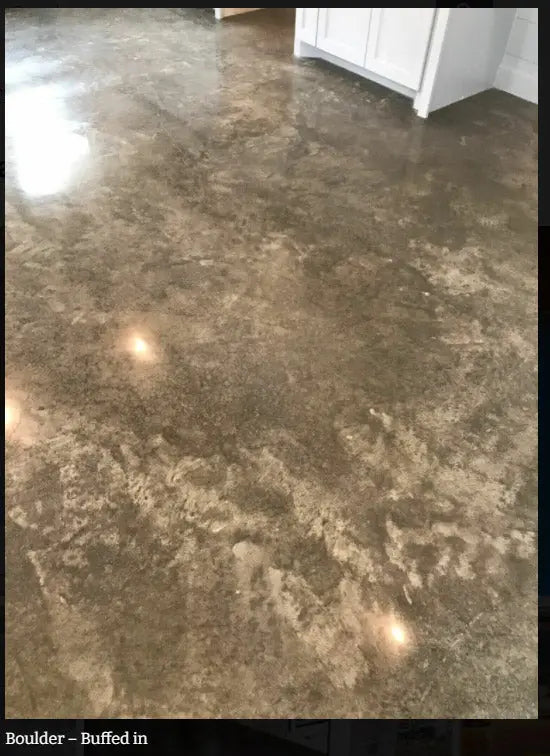

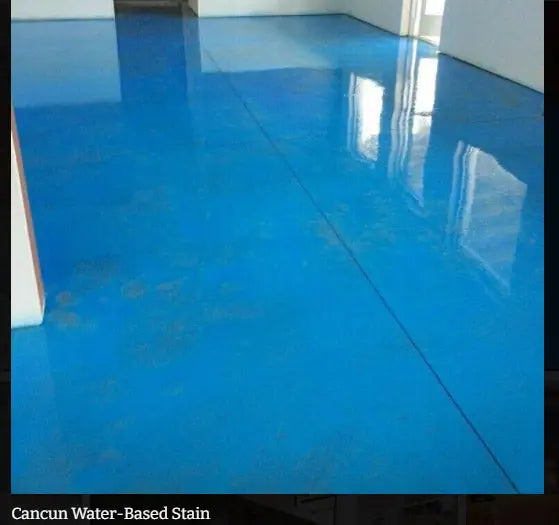

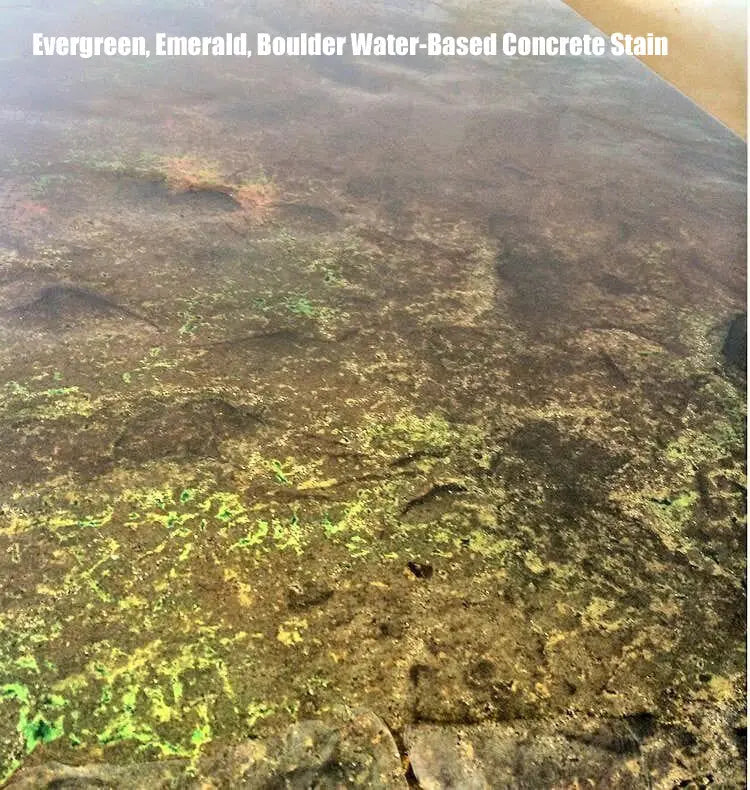

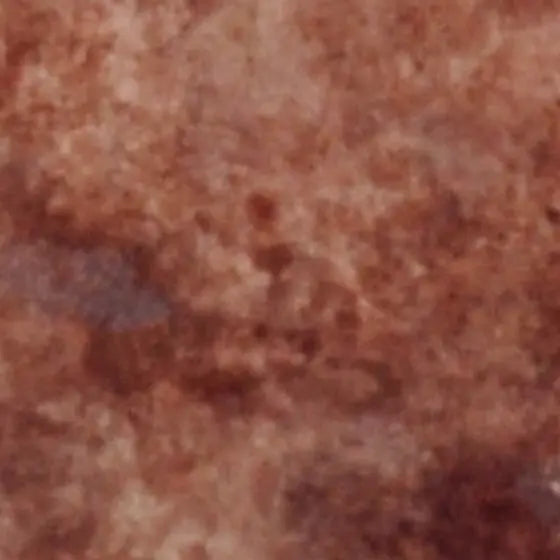

- Semi-translucent, easy to layer to achieve a mottled look

- Can be sprayed, rolled, brushed, or sponged

- Easy to dilute with water for a lighter coating/color

- UV stable for indoor and outdoor use

- Should be sealed to fully lock in color

Specifications Water Based Stain for Concrete - Tru Tint Waterbased:

-

Sold in Quart and Gallon Bottles (Sample 4oz size sold here)

-

Coverage: Quart: @60 sq. ft. per coat. Gallon: @250 sq. ft. per coat.

-

Typical application is 2 coats of stain

-

TDS Tru-Tint WB (Technical Data Sheet)

-

SDS Tru-Tint WB (Safety Data Sheet)

WHY USE Water Based Stain for Concrete - Tru Tint Waterbased?

-

Tru Tint WB from is a water-based semi-transparent formula of pigmentation designed to be used on a variety of cured concrete surfaces. The ease of use, and large color spectrum, makes it an easy choice for contractors and architects who need a simple color solution. Unlike traditional reactive type stains whose results can vary widely based on the uncertainty of that surface, Tru Tint WB produces very consistent results on a variety of surfaces both new and old. Tru Tint WB’s ease of use also makes it the de facto choice for correcting and/or enhancing existing color systems and projects

PREPARATION for Water Based Stain for Concrete - Tru Tint Waterbased:

-

If the concrete surface does not repel water and is not a really hard troweled surface then little or no prep work is required. Any previously applied sealer, paint or other oil based product must be removed to allow absorption. If the surface is a hard troweled surface or very smooth finish that Tru-Tint can not penetrate when tested then light sanding or light acid etching should be performed to “open up” the surface. TI C-A Etching Solution (sold here) is recommended. To test surface, just apply a small amount of Tru-Tint to the surface and wait for a couple of minutes. If the product does not soak into the surface and wipes up leaving little or no color, then the surface needs to be prepped by sanding or acid etching. Sanding Floor: Make sure that after sanding your concrete surface, you clean with a mild cleaner and brush to get all sand particles up from the pores of the concrete. Rinse well and if possible wet vac the surface while it is wet. Then test an area where it was sanded, with Tru-Tint WB Stain, to makes sure there is porosity in slab (and all dust is removed) resulting in effective staining.

APPLICATION for Water Based Stain for Concrete - Tru Tint Waterbased:

- Shake container thoroughly or mechanically mix prior to use to ensure full blending of the pigments. Verify all solid material is mixed up BEFORE using the stain, and shake stain periodically during use/spraying to ensure pigment doesn't settle. Tru-Tint WB can be sprayed, squirted, mopped, brushed, sponged or rolled. Care must be taken to avoid, or cover up, straight lines associated with rolling (unless straight lines are desired). Tru-Tint WB may be applied full strength or can be diluted with water to achieve a lighter hue. Tru-Tint WB color is built-up and may require repeat applications, depending upon the porosity of the concrete. It is not recommended for use on extremely porous substrates (concrete block or “just floated and broomed” surfaces). For extremely porous surfaces or on heavily sanded surface, you can add up to 1 pint of Water Based Acrylic Sealer (Stampsheen H20 sold here) into 1 gallon of Tru-Tint WB Stain, to help prime the porous concrete, and decrease the absorption which will give you the and help the stain color the top layer of the concrete. When using a single color of Tru-Tint WB, the first step is to apply completely over the entire surface. A single color of Tru-Tint WB in single application, achieves mottling by the varying degrees of porosity within the surface of the concrete. Additional “acid” like effects are achieved through further applications, either in complete coverage or random applications. Further applications depend upon desired look and porosity of the concrete.

-

When using multiple colors, apply the lighter colors first- However, yellow can be applied over red to “orange” it up a bit.

-

White Stain can be applied first, either in complete coverage or randomly, which results in more extreme mottling and a broader range of colors. The white base coat allows for brighter, more vibrant, colors. NOTE The White Tru Tint WB is of heavier pigment loading and care is recommended when applying white over other colors, as the white may be too overbearing. The white also shows settling, so keep product shaken or stirred.

-

Each coat contributes a little “primer effect” to the successive coat. Meaning that each additional coat may take longer to dry, and the latter application may be more pronounced.

-

The colors can be mixed in any fashion. They can be mixed together before application, and may actually separate a little to produce mottling by slightly different colors. More control and distinct colors is achieved by building one color on top of the other.

-

The edges of puddles will leave very distinctive veining, upon drying.

-

If some areas of the substrate are discovered to be much more porous than others, spend some time and product on these areas, before finishing the entire job. Always sample test an area for proper technique and results before actually using.

SEALING after using Water Based Stain for Concrete - Tru Tint Waterbased:

-

Follow the manufacturers’ guidelines of the sealer used. Remember, a water-based product has just been applied and different sealers have varying tolerance to additional moisture. The drying of Tru-Tint WB can be promoted by any means, not to exceed 200° F. Tru-Tint WB leaves an inert pigment upon drying. Slight residual material at the surface is acceptable; it will be incorporated into the sealer and bonded to the surface. However, White Tru-Tint WB should be completely dry and checked for residue if the sealer is being applied by any other means then spraying. The White can be picked-up and transferred by some sealers, especially if rolled to “tackiness”. If this transference of color is taking place, STOP! Additional drying time is probably needed. Switching to a sprayer for the first coat of sealer is another option. A lower solids level for the first coat of clear sealer is a third remedy. Allow 24 hours before permitting foot traffic on sealed area. Allow 72 hours before heavy traffic or vehicle traffic.

-

When dry, apply a sealer to lock in and preserve the color. For outdoors, a great sealer to use is StampSheen Sealer (sold here). For indoors, consider PolyAspartic 85 (sold here).

Because it actually penetrates the surface of the concrete and is designed to stand up to UV exposure, Tru Tint WB effects are permanent. Unlike paints and coatings, a concrete surface tinted with this water-based dye will not experience cracking or peeling of color: just apply, seal if desired, and admire!

Stain FAQ

Some of the simplest concrete staining systems available on the market are the Tru Tint WB water base stain system and Tru Tint Dyes. They are used on anything and everything concrete including but not limited to stamped and textured concrete, overlayments, microtopping surfaces, concrete counter tops, polished floors, decorative vertical concrete, concrete blocks and bricks, concrete pavers and even some wood surfaces. They are all about versatility and ease of use.

What is the difference between concrete stain and dye?

While many people use the terms interchangeably, there are some significant differences which need to be taken into account for each project. Note that in the following information, when referring to concrete stain we are NOT including concrete acid stains as they are completely different in nature.

Concrete stains, like Tru Tint WB, are more or less a suspension of fine pigment particulate in a carrier, usually a water base. This particulate is dispersed and spread onto the concrete, and the particles stay put once the carrier evaporates. They often contain a certain amount of resin, i.e. glue, to help them lock onto the surface. Due to different sizes of the particulate, the profile or “openness” of the concrete surface will determine how effective this type of product will be for you. The rougher, more “open” the surface is, the deeper and better the stain will adhere and grab onto the micro-surface that the concrete presents. Very smooth and burnished surfaces give stains the most trouble, since they provide very little for the stain to grab onto. Stamped or textured concrete surfaces, brush finished, and hand troweled surfaces work great for concrete stains such as Tru Tint WB. Concrete stain color pallets tend to be large and provide most needed tones, especially when mimicking the colors needed to replicate natural stone scapes as in stamping and texturing. Stains usually allow a fair amount of working time for faux finishing, i.e. layering, sponging, etc. and often allow for quick correction from overspray and spills. The color contained in stains tends to be hardy outdoors with good resistance to UV fade and, when on the right surface, will look great for a long time with proper care. Stains are usually applied by sprayer, brush, roller, etc.

Concrete dyes are also a pigment particulate, but they are many, many times smaller than what is contained in stains, and the pigments actually go into solution rather than a suspension. The carrier is often a solvent such as acetone or alcohol, though in the case of Tru Tint Dye, water is the preferred and safer carrier. The nature of dyes allows them to penetrate into the concrete almost regardless of the “openness” of the surface. A rough analogy is the stains are a form of paint, and dyes are more like an ink. Dyes are preferred for those burnished and polished surfaces that are going to be hard for stains to effectively penetrate. This often comes into play in commercial flooring and custom concrete countertops as those surfaces are often highly burnished or polished. Concrete dyes work fast and are not quite as forgiving with mistakes as stains. If using a solvent carrier they often dry almost instantly so leave little room for major error. Tru Tint dyes, blended as instructed with water, are far more forgiving and allow application by spray, roller or brush. Incidentally, polished surfaces tend to be indoors, which is good because that is another difference between the two product types. Dye particles do not exhibit good light fastness. In other words, they tend to fade in sunlight. That makes dyes a poor choice for patios, driveways, etc., where the color hardy stains thrive in sunlight. A few companies will claim their dyes are UV stable but that is a little misleading. In that case they added some UV absorbers into the product which does coat the dye particulate with that safeguard but it is often short lived as the absorbers have a short lifespan. The dye color pallet is usually a bit smaller than that of stains, but will still provide plenty of options for most projects.

How do I know if my cement surface is going to be stainable?

This is the type of information that is hard to answer because every surface is different and concrete pads tend to hold all sorts of invisible surprises that can affect a stain job. This is really where experience can really come into play. You have to be sure your surface is free of latent contaminants like grease, oil, paint, etc., anything that can impede the stain(or even dye) from getting into that surface. Even if it is squeaky clean, a surface still may have to be acid etched, ground, scarified or sanded to open the pores enough. An imperfect but quick test is to hose down your clean, dry surface lightly with water and watch how it absorbs into the concrete. It should immediately darken(wet out) and begin to absorb the water. Any beading or resistance you might see are areas that need to be addressed since the subsequent stain will be equally repelled.

Do I need to use a sealer?

Yes, a sealer is highly recommended to protect your concrete stain or dye from wearing away long term. Without a sealer, even though Tru Tint stains and dyes penetrate deeply into the substrate, the concrete can wear away along with the stain or dye. Most sealers will also enhance the look of a dyed or stained surface. The only exception would be a polished concrete floor or counter in which a dye would be used and often goes without a traditional sealer. Sealer application can be as soon as the stain or dye is thoroughly dry as long as other surface requirements are met regarding the chosen sealer.

Is high heat an issue when using either a stain or a dye as on a countertop?

Generally no. The stains or dyes will handle heat of that nature. Direct flames such as near a fire pit can darken/burn the surface as it would with any stone type surface.

Can I use concrete stains or dyes on natural stone? Yes, if the natural stone has not been sealed and is porous enough to allow the stain or dye to penetrate. A test area is recommended.

Do Tru Tint Stains or Dyes last long term?

Both concrete stains and dyes are manufactured to be as durable as possible. When your project is outdoors, a stain is preferred because it will not fade quickly. The dyes can lighten over time when subjected to UV light. This is a property of all dyes on the market. Otherwise, when applied to a properly prepared substrate and protected with the proper sealer either will last indefinitely.

When can I walk on a stained or dyed surface?

You can walk on a concrete stain or dye after it is dry to the touch. The length of time depends on temperature and humidity.

Do Tru Tint Stains or Dyes emit toxic fumes?

Tru Tint Stains and Dyes are formulated to be safe and ultra low VOC. Tru Tint dye can exhibit a mild odor but it is very short lived.

Can I stain or dye a freshly poured slab?

Yes, the typical 30 day wait period for new concrete really does not apply here. New concrete can be stained or dyed without affecting the concrete integrity. Be aware concrete lightens in color over time until fully cured therefore a newly stained or dyed slab will also change color as well.

Do Tru Tint Stains or Dyes chip or peel off the surface?

No. Unlike some concrete stains or dyes on the market which are more like paint, Tru Tint Stains and Dyes penetrate into the pores of the concrete so the substrate itself would have to chip.

What maintenance is required of a stained or dyed floor?

In general concrete that is stained or dyed requires very little maintenance and more durable than most flooring products. Once sealed, the surface should just be cleaned as needed and in accordance to any instructions given as it relates to the sealer. If the application is a textured floor then it is recommended to apply a sacrificial wax(such as Floorshine) over the sealer to minimize surface wear. This can be reapplied as part of a maintenance program. An exterior stain project may need a coat of sealer every 2 yrs. to enhance gloss and keep a protective layer.

What sort of coverage can I expect from a stain or dye?

Tru Tint Concrete Stain covers about 250 sq. ft. per gallon. The Tru Tint Dye covers about 300 sq. ft. per gallon. Variables that will affect the coverage rate are surface profile (a textured surface has more area and may need more) and porosity of the concrete. The more porous the substrate is the more stain it may take because it does not spread and is absorbs the color like a sponge. Application technique will affect how much is used. You should always avoid heavy pooling of either on the surface.